The Complete Guide to Barcodes You Didn’t Think You Needed (Until Now)

Learn everything you need to know about barcoding from generating your barcode to printing it on labels.

Table of content

-

Part I. Introduction

-

Part II. Types of Barcodes

-

Part III. Barcodes you Should Consider as a Small Business Owner

-

Part IV. What You Need to Create Your Own Barcodes

-

Part V. Printing Your Codes: Choosing your Barcode Printer

-

Part VI. Barcode Generator: Choosing your Barcode Software

-

Part VII. Label Material: Choosing Your Barcode Printing Paper

Part I. Introduction

What comes to mind when you think of barcodes?

If you think cashiers scanning products at a checkout line in a store, you get a cookie! That’s because retail stores are the biggest user base of barcode scanners.

But what seems most surprising is that some business owners are still of the view that barcode systems remain a preserve of large retail stores and supermarkets.

Well, they used to, but not anymore.

In truth, barcode scanners can be very much applicable in the small business setup irrespective of industry. As long as your business stocks products, a barcode scanner can prove a handy addition to your business toolkit.

If you own a products-based business that still relies heavily on conventional methods of inventory control like stock cards, you are doing yourself a huge disservice.

One of the most common arguments for the reluctance by some business owners to adopt a barcode system is that their business is not large enough to warrant one.

Others have the misconception that it is costly to implement. And of course, there are those who are wary of adopting a new system. Not that they are sworn technophobes, but they fear the supposed disruption that would impact on what is an already working system.

In reality, every business (large and small) can benefit from having a barcode system in place as it offers many more advantages besides keeping track of inventory, as we shall reveal in a bit.

As far as the small matter of cost goes, setting up barcoding is a largely inexpensive affair. The disruption too need not be overplayed as it can only be a good thing in this case.

Obviously, as a new business owner or an experienced one looking to leverage technology in your operations, understanding how a barcode system can fit into your business might not seem so straightforward in some instances. Good thing is, it is easy to understand with just a bit of explanation.

That is the purpose of this guide.

By the time you are done with it, you will have a solid grasp of what barcoding entails, and how you can go about implementing it in your company.

A Short History of Barcodes

Before venturing into the weeds, it would be prudent to define what a barcode is.

Barcodes are something you have seen on many product packages since your younger days, from food items to electronics.

But what are they exactly?

A barcode is basically a machine-readable code in the form of a pattern comprising lines, numbers, and in some cases symbols, that is printed on a product to help identify that product. These lines and numbers usually vary in width.

The barcode was the brainchild of Joseph Woodland, a mechanical engineer at Drexel University, Philadelphia. Invented in 1949, it has undergone continuous evolution over the years as new ways are conceived to incorporate more and more information on the code.

Being a representation of numbers and data, the creation of barcode patterns made it possible for optical scanning devices (read barcode scanners) to easily access basic information about a product and automatically relay this information to a computer system.

This was hugely beneficial in that it greatly shaved off the time it took to record such information as it did away with the need to key in information manually. More importantly, what it also did was eliminate the potential for human error as far as data entry was concerned.

Barcodes initially started out as basic one-dimensional patterns made up of simple black lines against a backdrop of white. These earlier patterns could only be interpreted by dedicated barcode scanners. And while the remnants of this early version are still prevalent, the landscape has considerably evolved.

Barcodes today come in a slew of shapes and sizes, not just lines and numbers – and their design varies.

As well, the number of devices that can interpret these codes is not just limited to the barcode scanner like before. We have a host of different devices capable of interpreting these codes now, including mobile phones (QR code, anyone?).

How Barcodes Work

To reiterate a previous point, a product’s data is contained in the pattern of lines and numbers that make up the code.

Translating it into comprehensible information involves scanning this code with a barcode scanner (or smartphone in some instances), following which it is then projected on the screen of – for purposes of brevity – a POS system.

The string of numbers at the bottom of the barcode is referred to as a Universal Product Code (UPC). It is this number that holds all the information attached to a given barcode.

The scanner cannot read these numbers as they appear. So, to access a product’s information, the scanner needs to decode the parallel lines on the code as these are the scannable portion of the UPC.

When a scanner reads the product’s code, the computer decodes the UPC number, then the information attributed to that number pops up on the screen.

For example, a code that appears as 014733345877 could be displayed on the cash register as follows:

Item #: 1234567

Description: Ray-Ban Sunglasses

Price: $42

Good question.

The relationship between the item and associated barcode has to be established in advance. The barcodes were generated either by the business itself or in conjunction with a global body known as GS1, a non-profit organization tasked with licensing barcodes to businesses the world over.

When you successfully register your company with GS1, you are assigned a set of numbers which go into the prefix of every code on your products. This number uniquely identifies your brand no matter where the product is scanned by a POS system in the world.

Unless you want to, you don’t necessarily have to register with GS1 to use barcodes. This is particularly if you sell your items directly to consumers through your online store or in person – be it in your brick-and-mortar store, at a farmers market, door-to-door and so on and so forth.

However, if your products will be moving through retailers like Walmart, Target and Amazon, you will be obliged to because one of their requirements is that their partners be holders of a GS1 certificate.

TL;DR (Too Long; Didn’t Read): You can identify the manufacturer of any product using the GS1 prefix – i.e. the first six digits of the item’s barcode.

Why Use Barcodes?

Now, to answer that all-too-important question of why you should invest in a barcode system for your business…

There are a number of ways small and medium business owners stand to benefit by implementing barcoding.

Reduced Risk of Error

As briefly alluded to earlier, keying in a series of numbers and letters that make up the UPC manually into a computer is liable to result in mistakes at one point or another.

As conscientious as you might be in your data entry, you risk hitting the wrong key on your keyboard by mistake every time you reach to track a package, ring up a customer, log inventory etc. etc.

Manual data entry is considered to have an average error rate of 1 percent, although it could be higher based on various human factors. And assuming it even remained at 1 percent, that could still mean a substantial number of records or fields keyed in erroneously.

Can your business afford to take that risk?

By comparison, barcode scanners have an accuracy rate of 1 error every 36 trillion characters.

Clearly, this is a case of human vs. machine. And the human loses out by some good margin.

Keeping Track of Inventory

One of the most obvious benefits businesses enjoy by having a barcoding system in place is the ease of keeping track of stock. A barcode scanner is part of a basic inventory tracking system that also includes its own software.

Every inventory item, from raw materials, to supplies, to the products you sell, has a barcode label such that when any item is removed from stock, all you need to do to update the available count is simply scan the item’s barcode as opposed to typing the entire stock keeping unit (SKU).

Saves Time

It’s not lost on anyone how laborious a process data entry can be. This is one of those areas where the human brain (or any other brain for that matter) is simply no match for a computer.

Sure, the time difference may be negligible in the case of small batches, but the hours will no doubt stack up over an extended time period. Time that could have been ploughed into something more meaningful.

The time benefit can also be felt directly by your customers at checkout.

While the nature of your business may not result in long queues at the checkout counter, everyone appreciates a fast checkout process. Hand-keying individual items is certainly not the idea of fast.

Ease of Updating Pricing

Updating your product pricing manually is another task that can gobble up time, particularly if your merchandise has price tags attached to it.

Instead of affixing price tags on individual items, it is better to do it on the product shelves or as signage, then use barcodes on the actual products.

What this does is result in less work when prices change, as they are bound to at some point. And when they do, all you will be required to do is amend the pricing once on the shelf signage and once in the barcode database, rather than swap every individual price tag.

Improved Inventory Control

As mentioned above, barcodes allow business owners to track inventory with unerring accuracy. This can help when you want to keep a low level of inventory, and it comes with the benefit of reducing overheads.

Additionally, it is possible to track the location of products, cutting down on the time spent searching – not to mention the money spent replacing items that are presumed lost.

Lower Operational Costs

The increased uptake of barcode systems has generally led to a reduction in barcode equipment acquisition costs. Put another way, the one-time cost you incur upfront these days is ultimately more cost-effective than paying staff to execute the same tasks week-in-week-out.

This is a benefit you are also likely to realize when it comes to your overheads. Since you have more accurate data, it becomes easier to reevaluate your expenses.

For example, if there are payments you are levying in the name of warehouse space, overestimating your inventory could turn out to be a money drain that might very well be avoided.

Deciding Whether Your Small Business is Ready for Barcodes

Barcodes may have their benefits, but they are one of those things – they can make your business operations easier, but your business can survive without them. Unless of course, you operate a retail store.

The thing is, you never really know how efficient barcodes could transform your operations until you have the system in place.

To determine if your business, be it brick-and-mortar or e-commerce-based, is ready for barcodes, there are a couple of pointers that could help you arrive at that conclusion more easily.

Consider implementing a barcode system if you meet one or more of the following criteria:

- Your business is product-based – doesn’t matter whether you are in the cake, fashion, or vehicle spare parts business

- You manage a lot of inventory

- You have more than one storage or retail location

- You work with other vendors, distributors, fulfilment services (like Amazon, for example) or other third-parties who will handle your product(s)

- You are not the only employee

- You want to stay on top of your inventory count

- You need to track shipments

- You are envisioning growth of the business

- You want to reduce customer waiting time at checkout

- You want to come across as more professional

You need not worry too much about snagging barcodes if:

- You can comfortably manage your inventory in-house without barcodes

- You don’t plan to wholesale or deal with distributors, fulfilment services, or other 3rd-parties to help sell, manage or store your inventory

Part II. Types of Barcodes

The world of barcodes is a vast one.

There are more than a dozen types of barcodes, some more recognizable than others. Although most serve the same purpose (product identification) some are best applicable in certain circumstances and systems, as we shall divulge a bit shortly.

The type(s) of barcode you decide to use in your business will depend on how you intend to use them and which part of the world you are selling in.

Generally speaking, however, all barcodes fall into three primary categories, depending on symbology. These are:

- Numeric-only barcodes

- Alpha-numeric barcodes

- 2-dimensional (2D) barcodes

The symbology is what determines how a barcode looks – the number of characters it can include, and the particular set of characters it can display.

Let’s explore this further.

1. Numeric-Only Barcode Symbologies

As the name suggests, these types of barcodes are made up of numbers only. Also known as one-dimensional (1D) or linear barcodes, numeric barcodes are the traditional form of barcodes and perhaps the most recognizable of them all.

If you observe closely, the width and spacing of the parallel lines on a numeric barcode varies systematically. This is completely by design – it is how these codes represent data.

Numeric-only barcodes are available in different symbologies:

- UPC Codes

UPC codes are one of the most recognizable barcodes for the sole reason that they are the most widely used codes on retail products. They were originally designed for use in grocery stores for inventory tracking and quick receipt printing. But they have since found widespread use in nearly every consumer product.

UPC codes come in two variations – UPC-A and UPC-E.

UPC-A is the standard variation and consists of 12 digits that carry basic information about the product manufacturer’s identity, as well as the product’s identification number and other information.

UPC-E is the more basic version and contains only 6 numbers. It is mostly used for smaller products.

- EAN Codes

Considered a superset of UPC, EAN stands for European Article Numbers. Although the abbreviation still stands, EAN today is used to mean International Article Numbers as they have been adopted worldwide.

This is a code designed for POS (point-of-sale) scanning and identifying consumer products.

The EAC code comes in different variations, including the more popular EAN-13, the compressed version that is the EAN-8, as well as JAN-13, ISSN and ISBN. The latter two are mostly used to track books.

Interestingly, when a UPC code goes through a scanner, it is converted into an EAN code of the 13-digit format.

- Industrial 2 of 5 Codes

Another type of 1D barcode, Industrial 2 of 5 codes consist of a pair of thick bars and three thinner bars, with the width between the bars fixed.

They are not as widely used as before, with their low density partly the reason they have waned in popularity. But you will still find them in some warehouses.

- ITF (Interleaved 2 of 5)

A modern version of the Industrial 2 of 5, the Interleaved 2 of 5 barcode retains the same format, albeit the width between the lines is not fixed.

This means the space width is also used to encode information in this case, as opposed to just the bars in the case of the Industrial 2 of 5.

This code can encode any even number of digits.

- Standard 2 of 5

Also similar to the Industrial 2 of 5, this barcode type preceded the Interleaved 2 of 5.

It was mostly applicable in warehouse sorting, airline ticketing and photo fishing, but no longer in common use today.

- Postnet

Short for Postal Numeric Encoding Technique, the POSTNET barcode is used by the US Postal Service for ZIP and ZIP+4 code encoding to help in directing mail and flagging errors more efficiently.

Its length can vary between 32 to 62 bars which also vary in height.

- Code 11

A 1D code whose name is evocative of a military top secret, Code 11 is popular in the telecommunications industry for labeling equipment.

But unlike a covert military operation, this high-density symbology has low security in that even a slight imperfection during print can result in bars rendering as alternate (yet valid) characters.

This is why you will find one or two check characters included in the code to circumvent this.

Code 11 encodes digits 0 through 9, and users in the United States might know it as USD-8.

- Codabar

Also known as USD-4 or ABC Codabar, this barcode symbology was a brainchild of Pitney-Bowes who developed it in 1972.

It can encode up to 16 characters, with wiggle room to include an extra 4 start/stop characters (A to D). The reason it is categorized as a numeric code is because its primary characters are all numeric.

Unless you work in a photo lab, this is not a code you will find yourself using in your business as it is mostly used in blood banks in the United States and on FedEx air bills.

2. Alpha-Numeric Barcode Symbologies

Alpha-numeric barcodes are another form of 1D barcodes, but unlike the numeric-only kind, these one come in a motley of letters and numeric characters.

Some symbologies under this category have been in use since the early days of barcodes, and you will find them on products spanning a gamut of industries, from food to defense.

They include the following:

- Plessey Code

Developed by the England-based The Plassey Company, the Plessey code has found common use in retail grocery shelves. This code was originally designed for use in libraries, although not so much today.

The Anker, MSI and Telxon barcodes are all variations that have been carved off of the Plessey code symbology.

These barcodes can support digits 0 to 9 and the letters A through F, although inclusion is mostly skewed towards numbers. This especially goes for the MSI Plessey which is predominantly used for inventory tracking.

This is why you might find Plessey barcodes being considered numeric-only in some cases.

Plessey code has a higher density than other commonly used symbologies such as Interleaved 2 of 5 or Code 39 (see below). But it encodes numbers poorly and this, coupled with other characteristics, makes it one of the most error-prone barcode languages.

- Code 39

This was the first alpha-numeric barcode to be developed.

Also known as Code 3 of 9, these barcodes are largely used in electronics, healthcare, automotive and defense sectors. Outside of retail applications, Code 39 is actually the most widely used barcode.

And for good reason. It can support the entire 128 ASCII character set and extend to any length, with the size of your label the only limitation. But if space is an issue, you might want to try Code 128.

The standard variation of Code 39 consists of 43 characters. These include letters (A to Z), digits (0 to 9), and some special characters (e.g. $ % . +), not to mention spaces. It does not support lower-case alphabets.

- Code 93

Also known as USS-93, Code 93 also supports the full ASCII character set.

Unlike Code 39, this one is more compact and boasts higher density and additional security within the code itself. For these reasons, Code 93s have the ability to remain shorter than their Code 39 counterparts.

It is mainly used in the logistics industry to label electronic components, as well as identifying packages in retail inventory. The Canadian Post also employs Code 93 to provide supplementary information regarding delivery.

- Code 128

Code 128 can do what Code 39 can, only better. It has good density and a broader character set.

The code is divided into subsets A, B, and C. A distinct start code determines which subset will be used, although there are control characters that allow you to switch to a different subset in the middle of a barcode should you wish to.

Code 128 is used mostly in non-POS application such as ordering and distribution in the logistics and transportation industries.

A good choice for your packaging and shipping needs.

3. Two-Dimensional Barcode Symbologies

2D barcodes encode data through a matrix structure that the eye perceives as a pattern of symbols and shapes like dots, squares and hexagons.

These codes represent data both vertically and horizontally. Hence the term two-dimensional.

This type of barcode is advantageous in that it can encode more information per unit area than its 1D counterpart. 2D codes are designed to hold up to 7,089 characters, a feat no 1D code can match.

With built-in self-checking and redundancy mechanisms, these codes also lead to fewer errors when deciphering data.

They are read using sophisticated scanners that include smartphones which simply take a snapshot of the code and decode it instantly.

Examples of 2D barcodes include newer barcode types like:

- QR Code

Yes, the ubiquitous QR codes are a form of barcode.

Short for quick-response code, you probably have used QR codes in your business for some form of advertising or marketing.

These codes are right at home on virtually any platform, whether we are talking physical products or digital platforms. All you need to interpret the code is scan the image using a smartphone and voila, message revealed.

QR codes are ideal for tracking and marketing initiatives, whether it be through digital business cards or magazines, linking to special offers and promos etc.

- Data Matrix

Another 2D code that is increasingly becoming prevalent, a data matrix has a tiny footprint, albeit capable of holding a vast amount of information.

This trait makes these codes ideal for use on small products, and the reason they have become a hit in industries like healthcare and manufacturing.

In fact, the US EIA (Electronic Industries Alliance) recommends their use on labeling of small electronic components.

As with their close cousin the QR code, data matrix codes have fast readability and high fault tolerance.

- PDF417

PDF417 codes come in handy when you want to store large amounts of data such as signatures, fingerprints and photographs.

They are capable of storing over 1.1 kb (that’s kilobytes) of machine-readable data, an attribute that makes them much more powerful than other two-dimensional codes.

As with QR codes, these barcodes are in the public domain, so are free to use.

- Aztec

This type of 2D code is commonly used in the transport industry. These are codes you have probably spotted in your ticket or airline boarding pass.

One notable upside of this barcode is that it can be decoded even when the resolution is bad. As well, it requires less space than a QR code, despite having the capability to hold more information.

Part III. Barcodes you Should Consider as a Small Business Owner

We know, while it would be nice to be privy to all the kinds of barcodes we have today, there are only so many you need as a small business owner.

We have broken them down to make it easier for you to choose the most practical code in different scenarios:

1. Barcodes for In-House Retail

If you want a barcode for your POS (point-of-sale) system and internal inventory management, there are a few barcodes you will find useful.

- Code 39 – One of the earliest and simplest barcodes. But remember, while it encodes alphanumeric characters, it only supports upper-case letters.

- Code 128 – This modern version of Code 39 is fast becoming the de facto standard barcode for most businesses. Reason is because most international barcodes (e.g. GS1-128, formerly UCC/EAN-128 or simply EAN128) have Code128 as the underlying barcode. If you regularly ship products, this is a barcode you are likely to be conversant with as many shipment companies and partners need it.

The one notable headache you’ll have to deal with when using this code is deciding which of its three subsets (A, B or C) would be most suitable.

Generally, though, use Type A if you want an alphanumeric code ( excluding lowercase alphabets), in addition to the first 31 ASCII characters. Type B supports alphanumeric with both uppercase and lowercase letters. And Type C will be ideal if you only have numbers.

- EAN-13 – Call it the retail barcode, the code that comes printed on the packaging of your favorite potato chips. This barcode replaced the original retail version used in North America (UPCA) in line with global standards. If you need a retail barcode as of today, this is your go-to code.

2. Barcodes for Global Retail

These two are the most widely used codes in the world for POS products and your choice will be guided by which corner of the world your products are selling in.

- UPC – Predominantly used in the US, Canada, UK and Australia. Most major retail products in these countries come with the UPC-A and UPC-E code variations. The former is the standard version and consists of 12 numbers. The latter is the condensed version and contains 6 numbers only, making it suitable for smaller products.

- EAN – Mostly used in Europe, Asia, Africa and Latin America. As previously mentioned, this code also has its own variations. In particular, the retail sector in these regions employs the EAN-13 symbology (made up of 13 numbers) and EAN-8 code (condensed version containing 8 digits).

3. Barcodes for Specialized Use

For example:

- UPC (Universal Product Codes) – Especially common in the countries we just mentioned above, these codes are widely used for inventory management and sales checkout in both retail and wholesale distribution.

- ITF (Interleaved 2 of 5) – Ideal for when you are shipping packaged products in corrugated boxes.

- QR (Quick Response Codes) – Perfect for your marketing and advertising initiatives.

4. Additional Questions to Help you Choose the Right Barcode

In addition to the above, there are 5 questions that can help you narrow down on the right code when deciding which barcodes to use for your operations:

-

What character sets should the barcode support?

Numeric only? Then UPC and EAN codes will do. Alphanumeric? Code 39 and Code 128 should suffice.

-

Will the code be scanned at a POS terminal?

Consider UPC and EAN.

-

What material do you intend to print the barcode on?

EAN codes are good for labeling products for POS scanning. When including promotional messages on digital marketing medium, QR codes are one of the best fits. Other codes like ITF work better on corrugated shipping boxes.

-

How much spacing is available on the product packaging?

UPC-E (the 6-digit UPC codes), EAN-8 (8-digit EAN codes), and Data Matrix take up very minimal space.

-

Which barcode can store the largest amounts of data?

None can do it better than PDF417.

Part IV. What You Need to Create Your Own Barcodes

And now to the fun part…

As we mentioned at the start of this guide, implementing barcodes is both simple and affordable. This is provided, of course, you have all the tools and materials you need.

Alternatively, you can always opt to have an outside supplier print your labels.

If you are looking to do it in-house, here is a list of what you will need.

1. Naming Convention

You need to figure out which barcode you will be using before all else. This is to avoid headaches later on as different barcode types accept different characters – something that could alter, or worse still, render your naming convention invalid.

Once that is done, design the graphic portion of the barcode. You might need to come up with the UPC information first before creating the graphic. This is the part that describes each of your products in a compressed series of letters and numbers.

You might also be required to register your company with GS1 depending on where you will be selling the items.

2. Inventory List

You need to have with you the number you will use to identify individual products in your point-of-sale system.

A product information sheet can minimize the hassle for you, so good if you have it.

3. Printer

If you have a working printer at home or work already, you are ready to go. Most standard inkjet and laser printers can print barcodes.

However, there is a caveat here. You need to evaluate your options for the best ROI if this is not a one-time thing – i.e. if you will be printing barcode tags regularly or in bulk.

For instance, a dedicated label printer is better suited for the job than say, a regular desktop printer which is only good for small batches.

4. Barcode Software

With the product names already identified, the process of designing the barcodes can now begin.

There are three ways you can go about this – four actually. You can choose to download barcode fonts from the multiple services that provide free barcode fonts, which you can then print from your computer.

Alternative, you can opt to use an online software (aka online barcode generator) which is probably the easiest of them all.

There are plenty of online generator services that don’t require much on your part. Most only need you to key in the code you came up with in Step (i) above, then download the barcode that will be generated for printing. Easy peasy.

The third option is to use a standalone software such as Microsoft Office and other specialized tools as we shall reveal in more detail later.

Lastly, some advanced POS systems (the same software connected to your scanner) also have a feature that allows business owners to print barcode labels from within the program. A good example is Lightspeed POS.

5. Barcode Labels

As you might probably have gathered, barcode labels are available in an array of standard sizes.

You can purchase them in rolls or sheets based on the type of printer you will be using.

As well, you need to decide on the type of material to use on your labels (paper or synthetic and their many variations). This is a decision that will be guided by factors such as type of printing method and the conditions the label will be exposed to.

Let’s look at the hardware, software and label material aspects in greater detail.

Part V. Printing Your Codes: Choosing your Barcode Printer

Finding the best printer, as with all printing solutions, will largely depend on what you intend to use it for.

In the case of barcode printers, getting clear on what you need from your hardware is a crucial first step to properly matching your technology to the job.

This is not something you want to overlook because doing so will leave you with a printer that either cannot meet your label demands or ends up being a resource guzzler. And that’s not what we want.

Before deciding on which label printer to invest in, consider this:

- How often will your business be printing labels?

- Will printing labels be an ongoing or temporary task?

- What size and shape of labels do you plan to print?

- What’s the number of labels that will be required on any one occasion?

- Is speed an essential in your label printing?

- Where does label quality rank in your requirements?

- Is label durability and longevity a big factor?

- Does your business require a portable printer device?

- Is color printing needed?

- How important is connectivity?

- What about integration with inventory and business management software?

Printing Technology: The Inkjet vs. Thermal Question

Before we dive into the types of label printers, let’s first introduce you to a pair of distinct label printing technologies you need to be aware of as this is one of the major decisions you will need to mull over.

1. Thermal Printing Technology

This technology relies on controlled application of heat to create images. There are two kinds of thermal printers:

Direct thermal printers – The thermal print head directly applies heat to a special kind of chemically-treated paper known as thermochromic paper until it turns dark. Limited to paper-based barcode printing, this printer does not involve any ribbons or ink. It can only create black and white images, and the images do not fade easily. For this reason, it is a popular candidate for printing barcode labels.

Thermal transfer printers – This one uses a ribbon to print labels on a variety of surfaces, not just paper. The ribbons are wax or resin-based. When a thermal print head applies to the ribbon, the surface of the ribbon melts, resulting in the wax or resin melting on the label to create the intended design. Colored ribbons allow for printing in color.

2. Inkjet Printing Technology

As with thermal printing, inkjet printing consists of two printing technologies, thermal and piezoelectric.

When considering an inkjet printer, you might be well served to go for the piezoelectric version.

It is more sophisticated, faster and accurate. It can create higher quality labels, thanks to the fine precision of its ink droplets. As well, the fact it is not dependent on heat means it can support even heat-sensitive inks.

What’s more, a piezoelectric inkjet is more efficient, cheaper to operate and lasts longer.

Now, Which is the Best Label Printer?

With those thermal and inkjet nitty-gritties out of the way, let’s compare the best barcode label printers on the market based on type.

Basically, you have the choice of four printers:

- Inkjet printers

- Thermal printers

- Dot matrix printers

- Laser printers

1. Inkjet Barcode Printers

These printers are perfect for high-speed production environments. They can churn out barcodes at a very rapid speed and have an ability to mark items fast.

While other printers will necessitate the adhesion of the barcode labels on the product or packaging, inkjet printers only need one more step to complete the process.

However, they come with a steep installation cost, and require more upkeep compared to thermal printers.

Items or materials with dark backgrounds also do not work well with inkjet printers as ink could bleed or legibility becomes an issue. If you decide to settle for this printer type, just make sure to get a scanner that can read the barcodes properly.

2. Thermal Barcode Printers

Thermal printers are advantageous in that they tend to product high-quality, long-lasting images. This has made them a popular feature in manufacturing settings.

Thermal transfer labels have a longer shelf life than those produced by direct thermal. Direct thermal tags are sensitive to abrasions, UV rays and heat, and this is why they require a coating on the paper to extend their longevity.

However, thermal transfer printer supply costs are a bit higher than direct thermal labels – not to mention the media and ribbon have to be compatible.

3. Dot Matrix Barcode Printers

This technology is the oldest method for producing on-site barcodes. These printers are easily accessible and are preferred by businesses for their cost-effectiveness, especially when printing in bulk.

They can also print barcodes on different surfaces and make use of multi-pass ribbons, a feature that lowers the cost of ribbons and labeling materials even further.

On the downside, labels printed in dot matrix printers are low- to medium-quality, making the barcodes hard to read. Not only that, while printing on multiple surfaces remains a huge plus, labels from a dot matrix printer are susceptible to the elements and do not last very long.

So, if quality and durability of labels is a priority, this is not the printer for you.

3. Laser Barcode Printers

The other option you should think about when shopping for a barcode label printer is the laser printer.

A laser printer is akin to a photocopy machine. It can print both barcode labels (high quality ones at that) and convert into a document printer when not printing labels. Any infrared scanner can easily read these barcodes due to their high density and resolution.

However, labels from a barcode printer are neither logical for small operations, nor ideal for industrial settings. Their durability is also very much wanting, given label printers cannot produce chemical- or water-resistant barcode labels.

Best Printer Models to Consider

It would be remiss to ink off on the subject of printers without touching on the actual models themselves, and the best options to consider in what is a sea of printers in the market.

For businesses looking to print barcodes in-house, there are many options available to you based on your work environment and needs of your business.

If we could namedrop a few, here are some we would recommend:

- Epson Expression ET-2650 – For businesses that do not print barcode labels regularly and do not find a dedicated printer for barcodes a necessity.

- Dymo Label Manager 420P – For businesses or anyone that wants to print their barcodes with a handheld device.

- cab XC Series – Thermal printers for businesses that need to add color to their labels with an additional ribbon. A high-resolution printer head ensures top of the line barcode labels. Includes the cab X4 and cab X6 models.

- Dymo LabelWriter – For retailers and ecommerce businesses that create barcode labels on a regular. It eliminates the use of ink or toner and can print labels directly from Word, Excel, QuickBooks and more.

- Zebra ZD500R – For businesses in need of a cost-effective model to print labels embedded with RFID wireless tracking chips.

- Zebra ZD410 – For manufacturers, warehouses and stores that print barcode labels in high volumes.

- Sato CL4NX – For businesses that need to create 2D barcodes. It is also an RFID label printer.

Part VI. Barcode Generator: Choosing your Barcode Software

Barcoding printers are only one aspect of a barcoding system. Before you take your labels to print, you need to have them designed in the first place.

Earlier on, we looked at the different ways you can design barcode labels, citing options like downloadable barcode fonts, use of barcode websites, as well as standalone programs.

It is to the latter we would like to shift your attention to.

Most barcode label software tend to be more than just a simple tool to design barcodes. They are advanced programs for carrying out tasks like asset tracking, workflow or sales funnel automation, inventory control, creating package labels, RFID tags etc.

In other words, barcode label design often isn’t the main offering in these applications, but rather an extra feature in the toolkit.

For this reason, they come at a cost. A cost many small business owners may not be able to justify. However, the upside to this is most of the programs are available in multiple pricing plans to fit different business needs.

Plus, if you reckon an inventory monitoring system would be a welcome addition to your modern business toolbox but are yet to incorporate one, this presents a full-hearted opportunity to refashion how you do business.

Still, if your aim is to simply design barcodes without the need for an advanced business program with too many bells and whistles – you probably already have an inventory management software in place – it wouldn’t hurt to explore basic options like Microsoft Excel and Word.

After all, you’ll find that even a good deal of these advanced programs design barcodes in a Microsoft Word-like environment.

The downside to using an Ms Office program as is, though, is that it is limited in terms of the codes you can create. For instance, it is possible to create Code 128 but not UPC or EAN codes.

That said, here are a few professional tools worth your consideration:

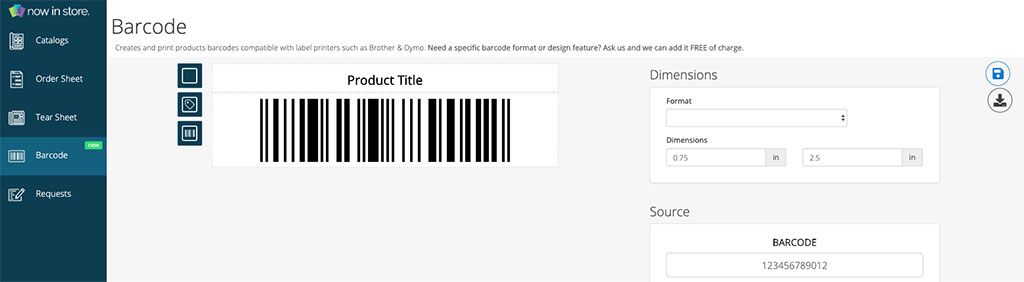

1. Now In Store

Of course we had to talk about our own solution! Our software is the new player on the barcoding market. We have several years of experience offering a solution to SMBs to create catalogs and we saw that there was a need for an affordable barcoding solution for SMBs.

We offer the only solution with an integration to e-commerce platforms such as Shopify, BigCommerce, Lightspeed, Magento, WooCommerce, ... Because of this integration, we can automatically generate barcodes for your products as soon as they are created. You can also directly print barcodes for a list of products or from specific orders. We support all types of paper (you can setup your own paper format) and all types of printers. In terms of barcode formats, we support the most popular used on the market and if yours is not supported, we can add it free of charge.

You can test our platform for FREE during 14 days at the following location:

Click here to register

2. BarTender

BarTender is one of the best barcode printing solutions out there.

The program, certified by GS1, is a complete solution that is more than just a barcode generation software. In addition to supporting RFID, it is also an inventory management tool that can serve both small to large businesses with hundreds of employees.

Sticking to barcode design, this program has a modern interface and intuitive design that makes it easy for users to navigate the platform without spending too much time figuring things out.

Its toolbar has a slew of practical tools that allow you to design, adjust and replicate any label you need. There is also a wizard to guide you when you are creating barcodes and linking to databases.

BarTender comes with over 400 preformatted barcode components (all ready to use) which inject some much needed efficiency into the task. It is supported by most printers you will be using so compatibility need not be a biggie.

If training and support is a swaying factor for you, few can rival Seagull Scientific (the name behind the software) on that front. Support is available during business hours and training is provided not just in documentation, but also through webinars, live online as well as in person.

3. EasyLabel

EasyLabel is another top barcoding software worth your consideration.

As with BarTender, it also doubles up as an RFID label software that lets you design smart labels, in addition to a raft of other features not necessarily attributed to barcodes.

What you will love about this offering from Tharo Systems is its ease of use. It has an easy-to-use interface which makes label design a cinch.

Matter of fact, you don’t need any skills out of the ordinary to work with EasyLabel. It incorporates a GS1 barcode wizard that simplifies your tasks even more, whether you are creating simple UPC codes or 2D barcodes.

The software is compatible with most popular printers, so you don’t have to worry about whether or not it will work with your current system.

Tharo offers great technical support to help you get the most out of the program. If you are based in the US, you are eligible for free support without any of those annual support contracts or fees you find with some brands.

While EasyLabel may not offer as advanced a repertoire of features as you are likely to get with BarTender, if you are on the hunt for an easy-to-use, efficient and cheaper option, you need look no further.

4. NiceLabel Designer Pro

NiceLabel has earned the title of one of the best barcode software tools available on the market today.

And for good reason.

The developers at NiceLabel have gone to great lengths to make this a user-friendly tool that lets users create top notch barcode labels for use in all industries across the board. One of the best features in this application is a tool known as EasyForm which enhances the software’s functionality.

NiceLabel gives you all essential features you need to create virtually any standard or custom barcode label. As with the other tools we have mentioned, this one also links to most databases. This means you can easily integrate the software with your other business systems.

While the interface may come across as a little bit dated compared to the other two programs or other solutions for that matter, don’t let the looks fool you. The software presents you with a rich assortment of useful tools and design options meant to help you fulfill your barcode printing needs.

It is compatible with multiple printers, it is cross-platform (same as the other two) and support is 24/7.

Other Worthy Options

In addition to the aforementioned three, here are a few other barcode design software that are worth your while:

5. ZebraDesigner Pro (by Zebra Technologies)

6. MarkMagic (by CYBRA Corporation)

7. Label Flow (by Jolly Technologies)

Part VII. Label Material: Choosing Your Barcode Printing Paper (Face Stock)

In addition to hardware and software considerations, choosing a material to print your barcodes is equally as important. This material is known as face stock in label printing circles.

Depending on the substrate the face stock is made from, the label could have a smooth, matte finish or boast an eye-catching glossy look. However, there is more to choosing the label face stock than just the aesthetics.

Ultimately, the decision should be majorly informed by what you intend to use the labels for and the environment they will be exposed to.

Face stocks used in the manufacture of barcode labels mainly come in two types:

- Paper – Mostly used for direct thermal printing. Paper labels are most suitable for general-purpose applications, inventory labeling, shipping labels and work-in-process (WIP).

- Synthetic – Synthetic barcode labels are primarily used for thermal transfer printing. This substrate is more durable and can resist the harsh elements, along with chemicals and abrasions. For this reason, it is the most ideal for harsh industrial conditions and products that will be used outdoors.

1. Paper Barcode Labels

Paper is the most popular face stock for packaging, shipping and general inventory tags. While it works well for most common applications, it is less durable.

Paper tags come in a number of variations:

- Coated or uncoated labels – Coated types are slightly more durable and less susceptible to tear than their uncoated counterparts.

- Thermal or laser-printed – The type of paper label you want will have a bearing on the type of printer you can use, or vice-versa. Thermal labels require (yup!) heat to print, while laser-printed labels are reliant on ink.

- Colored papers – White is usually the best option when it comes to barcode labels. While colored paper may be handy when you are color-coding, there is always the chance it might affect a barcode’s contrast, making it more difficult to scan.

- Gloss-coated or matte coatings – Glossy coatings enhance a label’s aesthetics. On the downside, though, they tend to reflect light which could result in a distorted barcode. This is why they are not widely used.

- Paper labels with wet-strength capacity – If you have products whose home is on the refrigeration isle, this is a good choice when printing your labels from paper. These labels have good water and dampness resistance, making them ideal for items that might be exposed to moisture.

2. Synthetic Barcode Labels

On the whole, however, they will require more outlay on your part in comparison to paper labels.

Synthetic barcode labels are also available in multiple materials:

- Polypropylene labels – These are plastic-based labels that are resistant to smears (water, oil, alcohol, chemicals) and general tear, including scratches. But generally, they have a low level durability compared to other synthetic face stocks on here. You will find them useful if you want barcode labels to aid in asset tracking. Other uses include usage in refrigerated or frozen food products, as well as pharmaceutical and hair care industries. They are only slightly more expensive than normal semi-gloss labels so they won’t blow a big hole in your budget. Plus, they are recyclable to appeal to the ‘greenie’ in you.

- Polyester labels – By far the most durable material for barcode tags, making it the go-to face stock for rugged settings and heavy use items. But due to its rigidity, it is not suitable for curved surfaces. Polyester is resistant to oil, water, chemicals and scratches, not to mention heat and UV exposure. It makes for outstanding print quality, but will require a full resin ribbon.

- Polyethylene (Polyolefin) labels – This synthetic face stock is well suited for curved surfaces such as vials or bottles. As with most synthetics, this flexible corona-treated material is resistant to water and chemicals.

- Polyimide labels – This is a polymeric plastic material specially made for long-term durability. It can withstand temperatures as high as 250°C (approximately 500°F). It is very stable in terms of its thermal properties, making it an ideal choice for use in electronics.

- Vinyl labels – Vinyl is another material you can use to print your barcode labels. What you will love about it is its flexibility (which makes it good on curved surfaces), versatility and also importantly, its cost-effectiveness. However, this is not the tag you want if you are looking for a material that can withstand harsh indoor and outdoor conditions. It is more durable than paper, though, and if you want to increase its durability, consider adding a strong over-laminate that can withstand harsh conditions and settings.

Wrap Up

As you can see, barcode design is not as straight forward an affair as it may appear. There are a handful of imperative factors you need to think about if you are to come up with best-selling tags to flank your products irrespective of market, setting or platform.

With this guide, we hope we have provided you with the most essential aspects of barcode design that will guide you towards successful barcode system implementation in your enterprise, regardless of the industry.

Here’s to great designs!